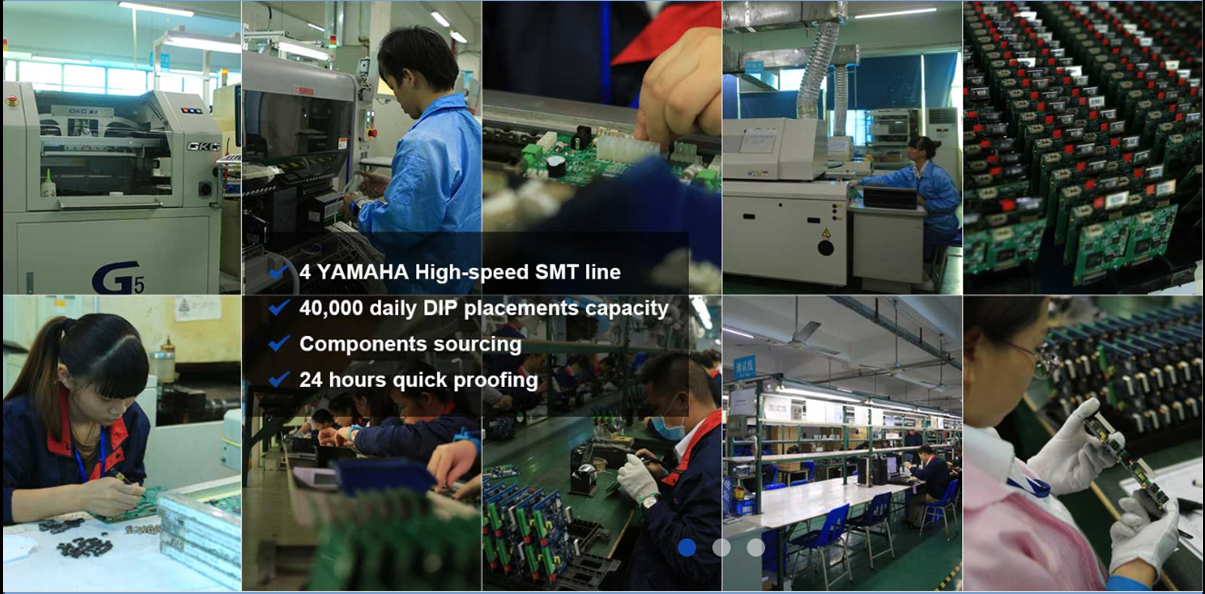

● 4 YAMAHA High-speed SMT Lines

● 6 million daily SMT placements capability

● 400,000 daily DIP placements capability

● 500×600 mm Maximum Board Size

● 0.25"x 0.25" Minimum Board Size

● 450 mm Max. Width for Wave-Solder

● Passives Components Down to 0201 Size BGA and VFBGA Leadless Chip Carrier/CSP Double-Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and Replacement

SMT and DIP/X-RAY Inspection/AOI Testing/In-circuit-test (ICT)/Flying Probe/Function Test/Burn-in/Finished products assembly.

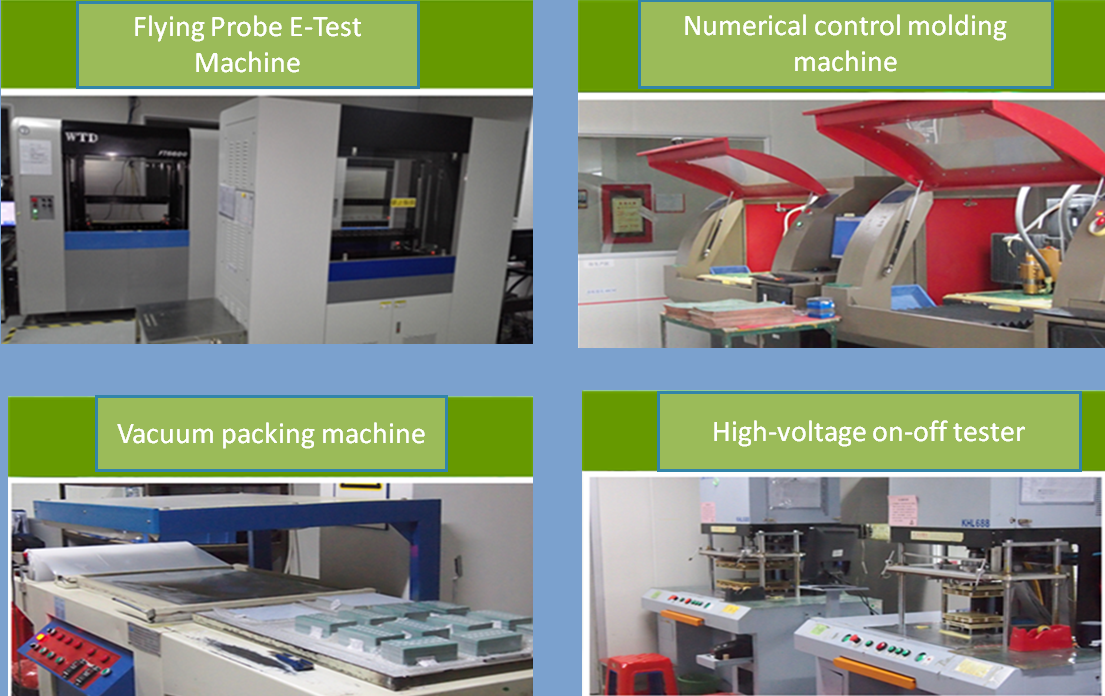

PCB processing capability

| PCB service | Process capability |

| Layer | 1-20 layers |

| Maximum size | ≤600*500mm |

| Thickness | 0.1-5.0mm |

| Wire copper foil thickness | 17-343um(10oz) |

| Minimum linewidth / line distance | 0.075/0.065mm(3mil/2.8mil) |

| Minimum aperture | 0.15mm(6mil) |

| Minimum welding pad | 0.2mm(8mil) |

| Impedance control | +/-10% |

| Shape processing accuracy | +/-0.10mm(4mil) |

| Board type | FR-4, aluminum - base, copper -base, ROGERS, ARLON, Teflon, composite |

| Surface treatment | Tin spray, ENIG, Immerse Au, immersion silver, im mersion tin, osp, gold osp, electrospray tin |

PCB ASSEMBLY CAPABILITY

| SMT service | Process capability |

| Processing type | SMT, DIP, After welding, test |

| Maximum board | L50×W50mm~L510×W460mm |

| Maximum thickness | 3mm |

| Minimum thickness | 0.5mm |

| Minimum component | 1005 |

| Maximum component size | 150mm*150mm |

| Minimum pin component spacing | 0.3mm |

| Minimum bga spacing | 0.3mm |

| Maximum component mounting accuracy(100FP) | Whole assembly accuracy up to ±50 micron,whole process repetition accuracy ±30 micron. |

| SMT capacity | 4 million pins / day |

| DIP capacity | 100 thousand/ day |