● 4 YAMAHA High-speed SMT Lines

● 6 million daily SMT placements capability

● 400,000 daily DIP placements capability

● 500×600 mm Maximum Board Size

● 0.25"x 0.25" Minimum Board Size

● 450 mm Max. Width for Wave-Solder

● Passives Components Down to 0201 Size BGA and VFBGA Leadless Chip Carrier/CSP Double-Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and Replacement

SMT and DIP/X-RAY Inspection/AOI Testing/In-circuit-test (ICT)/Flying Probe/Function Test/Burn-in/Finished products assembly

What is thick copper PCB?

With the rapid development of the electronic information age, the demand for pcb, such as high-power and large-current server power panel, is increasing. Importantly, these power boards require high heat resistance, high heat dissipation. PCB designers would love to design it as thick copper boards. The extra copper PCB thickness allows the board to conduct higher currents, achieving good heat distribution, and implement complex switching in a limited space.

Some other advantages include increased mechanical strength of the connector location, the ability to create smaller product sizes by integrating multiple weights on the same layer of circuitry, and the ability to use special materials to achieve their maximum capacity and minimize the risk of circuit failure.

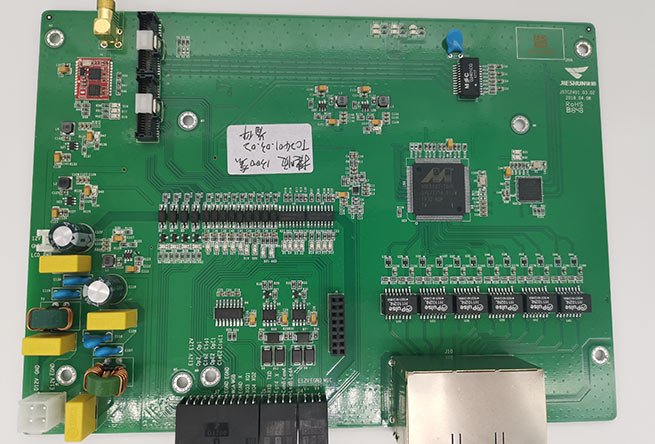

CTT is a highly skilled PCB manufacturer that develops and produces high quality thick copper PCB. We offer thick copper PCB manufacturing services using up to 15 ounces (525 microns) of copper weight.

CTT has 18 years of experience in manufacturing and assembling high performance standards and thick copper PCB products to help our customers achieve their productivity and profitability goals. We set it a standard operating procedure, allowing our highly skilled engineers to solve all problems and concerns before production. It ensures that the finished printed circuit board meets your performance expectations. Our quality control department guarantee the quality of printed circuit boards.

Check our thick copper PCB capabilities as below list:

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL - Hot Air Solder Leveling |

| Lead Free HASL - RoHS | |

| ENIG - Electroless Nickle/Immersion Gold - RoHS | |

| Number of Layers | 2 - 20layers |

| Build Time | 2days - 5weeks |

| Material | FR-4, MCPCB, copper PCB、ROGERS、ARLON、Teflon、Composite PCB |

| Board Size | Max 500mm x 600mm |

| Board Thickness | 0.6mm - 6.5mm |

| Max Outer Layer Copper Weight (Finished) | 15oz |

| Max Inner Layer Copper Weight | 12oz |

| Min Tracing/Spacing | For External layers: |

| 4oz Cu 9mil/9mil | |

| 5oz Cu 11mil/11mil | |

| 6oz Cu 13mil/13mil | |

| 12oz Cu 20mil/32mil | |

| 15oz Cu 32mil/40mil | |

| For Internal layers: | |

| 4oz Cu 8mil/12mil | |

| 5oz Cu 10mil/14mil | |

| 6oz Cu 12mil/16mil | |

| 12oz Cu 20mil/32mil | |

| Min Annular Ring | 6mil |

| Min Drilling Hole Diameter | 10mil |

| Other Techniques | Gold fingers |

| Blind/Buried Vias |

Get an instant Quotation for Your Thick Copper PCB Project now? Click your favorite button in the right side.