Brand Name: HK CT TECH

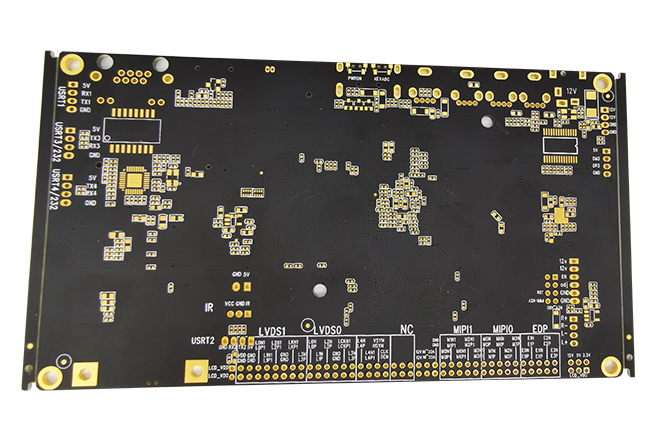

Model Number: OEM PCB design

Base Material: fr-4 flex-rigid pcb board, Fr-4,ALu,Roger,leadfree

Copper Thickness: 1oz

Board Thickness: 1.6mm

Surface Finishing: imersion gold

Product name: HK CTT Quick Prototype Power Printed Circuit Board

Function: PCBA Board Service Prototype PCB Assembly

surface finishing: imersion gold/tin/Au/silver/tin,Osp,Hasl

Application: Consumer Electronics

Solder mask color: Green\White\Red\Blue\Black

PCBA type: Electronics Manufacturing board

Layer: 1-48 Layers (include Rigid-Flex PCB)

Analysis of some phenomenon in PCB fabrication:

Issue:

There is too much residue on the PCB board surface after soldering, and the board is dirty.

Result analysis:

(1) The temperature is not preheated before welding or the preheating temperature is too low, and the temperature of the tin furnace is not enough;

(2) The speed of the board passing is too fast;

(3) Antioxidant and anti-oxidation oil are added to the tin liquid;

(4) too much flux coating;

(5) The component feet and the orifice plate are not proportional (the holes are too large), so that the flux is accumulated;

(6) During the use of the flux, no diluent is added for a long time.

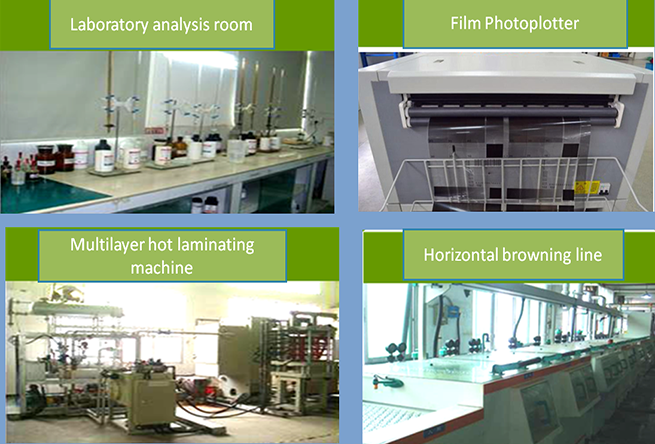

PCB processing capability

| PCB service | Process capability |

| Layer | 1-20 layers |

| Maximum size | ≤600*500mm |

| Thickness | 0.1-5.0mm |

| Wire copper foil thickness | 17-343um(10oz) |

| Minimum linewidth / line distance | 0.075/0.065mm(3mil/2.8mil) |

| Minimum aperture | 0.15mm(6mil) |

| Minimum welding pad | 0.2mm(8mil) |

| Impedance control | +/-10% |

| Shape processing accuracy | +/-0.10mm(4mil) |

| Board type | FR-4, aluminum - base, copper -base, ROGERS, ARLON, Teflon, composite |

| Surface treatment | Tin spray, ENIG, Immerse Au, immersion silver, im mersion tin, osp, gold osp, electrospray tin |

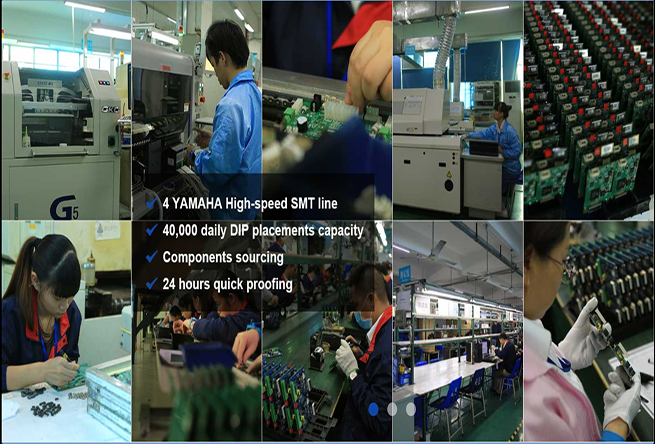

PCB ASSEMBLY CAPABILITY

| SMT service | Process capability |

| Processing type | SMT, DIP, After welding, test |

| Maximum board | L50×W50mm~L510×W460mm |

| Maximum thickness | 3mm |

| Minimum thickness | 0.5mm |

| Minimum component | 1005 |

| Maximum component size | 150mm*150mm |

| Minimum pin component spacing | 0.3mm |

| Minimum bga spacing | 0.3mm |

| Maximum component mounting accuracy(100FP) | Whole assembly accuracy up to ±50 micron,whole process repetition accuracy ±30 micron. |

| SMT capacity | 4 million pins / day |

| DIP capacity | 100 thousand/ day |