Company News

Aug. 21, 2024

There is a key component in the electronics industry called PCB (printed circuit board). This is a too basic part, making it difficult for many people to explain exactly what a PCB is. The PCB board manufacturer will explain in detail the composition of the PCB and some terms commonly used in the field of PCB.

In the next few pages, we will discuss PCB making, including some terms, a brief assembly method, and an introduction to the PCB design process.

PCB (Printed circuit board) is the most common name, it can also be called "printed wiring boards" or "printed wiring cards". Before the advent of PCBs, circuits were made up of point-to-point wiring. The reliability of this method is very low, because as the circuit ages, the rupture of the line will cause the circuit node to open or short.

Winding technology is a major advance in circuit technology. This method improves the durability and replaceability of the circuit by winding small-diameter wires around the posts at the connection points.

When the electronics industry develops from vacuum tubes and relays to silicon semiconductors and integrated circuits, the size of electronic components has decreased and prices have also fallen. Electronic products are appearing more and more frequently in the consumer sector, prompting manufacturers to look for smaller and more cost-effective solutions. So PCB was born.

Composition:

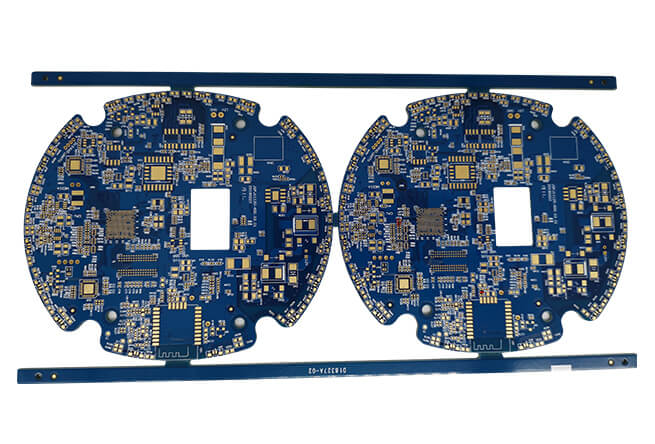

Pcb Board

The PCB board looks like a multi-layer cake or lasagna-layers of different materials are pressed together in the production by heat and adhesive.

Start with the middle tier.

The substrate of PCB is generally glass fiber. In most cases, the glass fiber substrate of PCB is generally referred to as "FR4". The solid material "FR4" gives PCB hardness and thickness. In addition to FR4, there are also flexible circuit boards produced on flexible high-temperature plastics (polyimide or similar).

You may find PCBs with different thicknesses; however, most of SparkFun's products are 1.6mm (0.063 ’’). Some products also use other thicknesses. For example, LilyPad and Arudino Pro Micro boards use a thickness of 0.8mm.

Cheap PCBs and hole boards (see above) are made of materials such as epoxy or phenol. They lack the durability of FR4, but they are much cheaper. When welding something on this board, you will smell a big odor. This type of substrate is often used in very low-end consumer products. Phenols have a low thermal decomposition temperature. Excessive welding time will cause them to decompose and carbonize, and emit an unpleasant smell.

Copper:

The following is a very thin copper foil layer, which is pressed on the substrate by heat and adhesive during production. On double-sided boards, copper foil is pressed to the front and back of the substrate. In some low-cost applications, copper foil may be pressed on only one side of the substrate. When we refer to "dual-panel" or "two-layer board", it means that we have two layers of copper foil on the lasagna. Of course, in different PCB designs, the number of copper foil layers may be as few as one layer, or more than 16 layers.

There are many types of copper layer thicknesses, and weight is used as a unit. Generally, copper covers a square foot of weight (ounce oz). The copper thickness of most PCBs is 1oz, but some high-power PCBs may use 2oz or 3oz copper. Convert the ounce (oz) per square foot, which is about 35um or 1.4mil copper thickness.

Soldermask:

Above the copper layer is a solder mask. This layer makes the PCB look green (or SparkFun's red). The solder mask layer covers the traces on the copper layer to prevent the traces on the PCB from contacting with other metals, solder or other conductive objects to cause short circuits. The presence of a solder mask layer allows everyone to solder in the right place and prevents solder bridges.

The solder mask covers most of the PCB (including the traces), but the silver ring ring and SMD pads are exposed for easy soldering.

Generally, solder masks are green, but almost all colors can be used for solder masks. Most of SparkFun's boards are red, but IOIO boards are white, and LilyPad boards are purple.

Silkscreen:

Above the solder mask, there is a white silkscreen layer. Letters, numbers, and symbols are printed on the silkscreen layer of the PCB, which can facilitate assembly and guide everyone to better understand the design of the card. We often use the symbols of the silk screen layer to indicate the functions of certain pins or LEDs.

The most common color of the screen printing layer is white. Similarly, the screen printing layer can be made into almost any color. Black, gray, red and even yellow silkscreen layers are not uncommon. However, it is rare to see multiple silkscreen layer colors on a single board.