Company News

Aug. 21, 2024

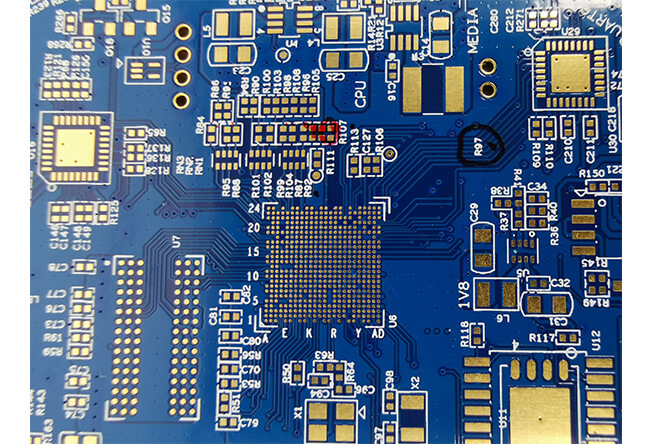

Introduction of ICT testing technology in PCBA testing shared by SMT PCBA processing.

During ICT testing, the test probe is mainly used to contact the test points on the PCBA board, which can detect the short circuit, open circuit, component welding and other fault problems. Can quantitatively on the resistor, capacitor, inductor, crystal and other device to measure, the diode, triode, light lotus root, transformers, relays, operational amplifier, power supply module function test, for small and medium scale integrated circuit function test, such as all 74 series, the Memory type, commonly used driver IC, exchange, etc.

Some approaches to ICT testing are;

1. Simulator test

Test with operational amplifier. The concept of "virtual land" from "A" point is as follows:

∵ Ix = Iref

∴ Rx = v/where V0 * Rref

Vs and Rref are respectively excitation signal source and instrument calculated resistance. If we measure V0, then Rx can be solved. If the Rx to be measured is capacitance and inductance, then Vs ac signal source and Rx is impedance form, C or L can also be solved.

2. Vector test

For digital IC, Vector test was adopted. Vector testing is similar to the measurement of truth table, which can stimulate input vector and measure output vector, and judge the quality of devices through the actual logic function test. Such as: and not gate test.

Analog IC test, according to the actual function of IC excitation voltage, current, measurement of the corresponding output, as a function block test.

3. Non-vector tests

With the development of modern manufacturing technology and the use of vlsi, it often takes a lot of time to write the vector test program of devices, such as the 80386 test program takes a skilled programmer nearly half a year. The large number of applications of SMT devices make the fault phenomenon of open pin become more prominent. To this end, the companies non - vector testing technology, Teradyne launched MultiScan; GenRad - driven Xpress non - vector testing technology.

ICT test is at the back end of the production process, the first step of PCBA test, which can timely find problems in the production process of PCBA board, and help to improve the process and improve the production efficiency.

That's all for the sharing, thanks for your reading, and we also supply Cheap LED Printed Circuit Board for sale, if you have any demand for our products, just feel free to contact us.

Previous: Analyze tips for cleaning PCB boards