Company News

Aug. 21, 2024

6.Drilling

To connect the four layers of non-contact copper foils in the PCB together, firstly drill up and down through holes to punch through the PCB, and then metalize the hole walls to conduct electricity.

Use an X-ray drilling machine to locate the inner core board. The machine will automatically find and locate the hole positions on the core board, and then punch the PCB with positioning holes to ensure that the next hole is drilled from the center of the hole. Too.

Put a layer of aluminum plate on the punch machine, and then place the PCB on it. In order to improve efficiency, 1 to 3 identical PCB boards are stacked together for perforation according to the number of layers of the PCB. Finally, the top PCB is covered with a layer of aluminum plate. The upper and lower layers of aluminum plate are to prevent the copper foil on the PCB from tearing when the drill bit is drilled in and out.

In the previous lamination process, the melted epoxy was squeezed out of the PCB, so it needed to be removed. The profile milling machine cuts the periphery of the PCB according to the correct XY coordinates of the PCB.

7.Chemical precipitation of copper on the pore wall

Since almost all PCB designs use different layers of wiring to connect through holes, a good connection requires a 25 micron copper film on the hole wall. This thickness of copper film needs to be achieved by electroplating, but the hole wall is made of non-conductive epoxy resin and glass fiber board.

So the first step is to first deposit a layer of conductive material on the hole wall, and form a 1 micron copper film on the entire PCB surface, including the hole wall, by chemical deposition. The entire process, such as chemical treatment and cleaning, is controlled by the machine.

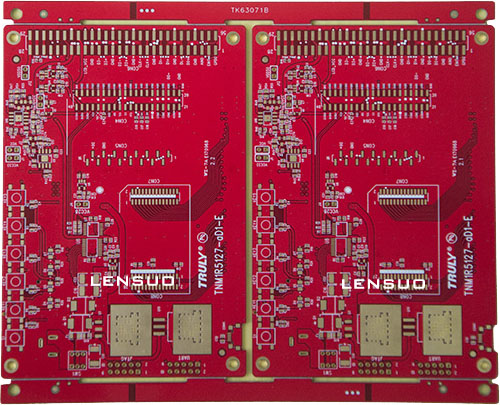

PCB Board

8.Transfer of outer PCB layout

Next, the PCB layout of the outer layer is transferred to the copper foil. The process is similar to the principle of the previous PCB layout transfer of the inner core board. The photocopying film and photosensitive film are used to transfer the PCB layout to copper foil. Yes will use positive film for the board.

The inner PCB layout is transferred using a subtractive method, and a negative film is used as the board. The PCB is covered by the cured photosensitive film for the circuit. The uncured photosensitive film is cleaned. After the exposed copper foil is etched, the PCB layout circuit is protected by the cured photosensitive film and left.

The outer PCB layout is transferred using the normal method, using positive film as the board. The non-circuit area is covered by the cured photosensitive film on the PCB. After the uncured photosensitive film is washed away, plating is performed. Where there is a film, it cannot be electroplated, but without a film, it is plated with copper and then tin. After the film is removed, alkaline etching is performed, and finally tin is removed. The circuit pattern is left on the board because it is protected by tin.

Clamp the PCB with a clip and electroplat the copper. As mentioned earlier, in order to ensure sufficient conductivity at the hole position, the copper film plated on the hole wall must have a thickness of 25 microns, so the entire system will be automatically controlled by the computer to ensure its accuracy.

9, outer PCB etching

Next, a complete automated assembly line completes the etching process. First, clean the cured photosensitive film on the PCB board. Then remove the unnecessary copper foil covered with strong alkali. Then remove the tin plating layer on the copper foil of the PCB layout by using a desoldering solution. After cleaning, the 4-layer PCB layout is complete.

We are automotive PCB manufacturer. We provide cheap PCB. If you have any demand for our products, please feel free to contact us.

Previous: None

Next: How Was Pcb Born?(Up)