Company News

Aug. 21, 2024

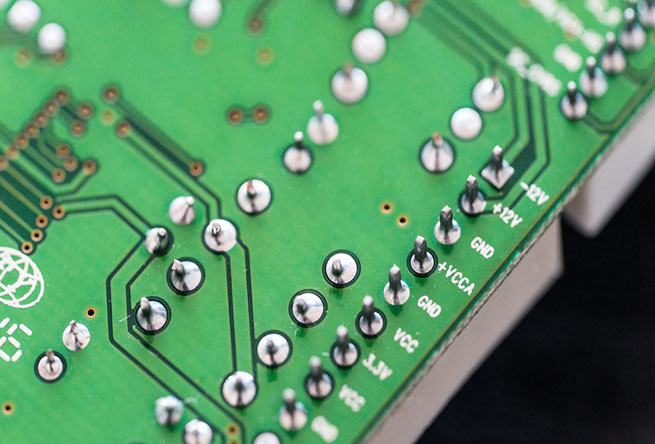

PCB board manufacturer to share with you: the current circuit board, mainly consists of the following:

1. Circuit and Pattern: The circuit is used as a tool for the conduction between the originals. In design, a large copper surface will be designed as the ground and power layer. The lines and drawings are made at the same time.

2. Dielectric layer: used to maintain the insulation between the circuit and the layers, commonly known as the substrate.

3. Through hole: Vias can connect more than two levels of lines to each other. Larger vias are used as component inserts. Non-through holes (nPTH) are usually used as Surface mount positioning for fixing screws during assembly.

4. Solder resistant / Solder Mask: Not all copper surfaces need to eat tin on parts, so non-tin eaten areas will be printed with a layer of insulation material (usually epoxy resin) on the copper surface To avoid short circuit between non-tin-eating lines. According to different processes, it is divided into green oil, red oil, and blue oil.

5. Silk screen (Legend / Marking / Silk screen): This is an unnecessary structure. The main function is to mark the name and location frame of each part on the circuit board for easy maintenance and identification after assembly.

6. Surface Finish: As the copper surface is easily oxidized in the general environment, it can not be tinned (poor solderability), so it will be protected on the copper surface to eat tin. The protection methods are HASL, ENIG, Immersion Silver, Immersion TIn, and Organic Solder Flux (OSP). Each method has advantages and disadvantages, which are collectively referred to as surface treatment.

Pcb Board

PCB board features

1. Can be high density: For decades, the high density of printed boards has been able to develop with the integration of integrated circuits and advances in installation technology.

2. High reliability: Through a series of inspections, tests and aging tests, it can ensure that the PCB can work reliably for a long time (usage period, generally 20 years).

3. Designability: For various performance (electrical, physical, chemical, mechanical, etc.) requirements of the PCB, printed board design can be achieved through design standardization, standardization, etc., with short time and high efficiency.

4. Producibility: It adopts modern management, which can carry out standardization, scale (quantity), automation and other production to ensure consistent product quality.

5. Testability: Established relatively complete test methods, test standards, various test equipment and instruments to test and identify the qualification and service life of PCB products.

Assemblability: PCB assembly can be automated and mass-produced. At the same time, PCB and various component assembly parts can be assembled to form larger parts and systems, up to the whole machine.

6. Maintainability: Since PCB products and various component assembly components are standardized design and large-scale production, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, easily and flexibly, and the system can be quickly restored to service. Of course, you can give more examples. Such as making the system smaller and lighter, and speeding up signal transmission.

Integrated circuit features: The integrated circuit has the advantages of small size, light weight, fewer lead wires and solder joints, long life, high reliability, good performance, etc. At the same time, the low cost facilitates mass production. It is widely used not only in industrial and civilian electronic equipment such as radio cassette recorders, televisions, computers, etc., but also in military, communications, remote control, etc. The use of integrated circuits to assemble electronic equipment can increase assembly density by several tens to thousands of times over transistors, and the stable working time of the equipment can be greatly improved.

Difference between PCB board and integrated circuit

The integrated circuit generally refers to the integration of chips. Like the Northbridge chip on the motherboard, the internal CPU is called an integrated circuit, and the original name is also called an integrated block. The printed circuit refers to the circuit boards and the like that we usually see, and there are solder chips printed on the circuit boards.

The integrated circuit (IC) is soldered on the PCB; the PCB version is the carrier of the integrated circuit (IC). The PCB board is a printed circuit board (PCB). Printed circuit boards are found in almost every electronic device. If there are electronic parts in a certain device, the printed circuit boards are mounted on PCBs of different sizes. In addition to fixing various small parts, the main function of the printed circuit board is to electrically connect the various parts on it.

To put it simply, integrated circuits are a general circuit integrated into a chip, which is a whole. Once it is damaged internally, the chip is also damaged, and the PCB can solder components by itself, and can be replaced if it is broken.

Previous: What Is A Pcb?