Company News

Aug. 22, 2024

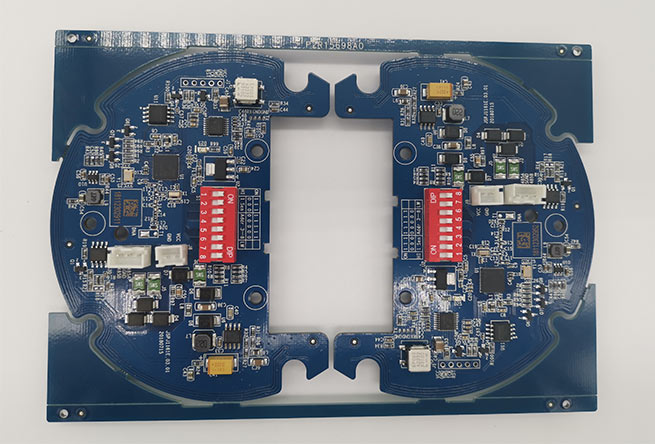

Contact welding technology for SMT assembly

Repair SMT PCBA processing requires excellent technical operators and good tools to closely cooperate, repair must be careful, the basic principle is not to make the circuit board, components overheating, otherwise it is very easy to cause damage to the circuit board's electroplating through hole, components and solder plate. Here are some common SMT component repair welding techniques.

Contact welding. Contact welding is characterized by the use of heated electric soldering tip or ring in direct contact with the welding medium, after a certain period of time in a specific position to form an acceptable solder joint, the welding medium including pads, solder wire, flux and other substances.

The welding head is used to heat a single welding point, while the welding ring is used to heat multiple welding points at the same time. Welding head has a single head, double head or surrounded by a variety of forms, mainly for the removal of components. The shape design of the welding ring is mainly used for the disassembly and welding of multi-pin components encapsulated by bilateral and peripheral pins, such as the disassembly and welding of integrated circuits and other components.

Contact welding repair systems come in a variety of sizes and are usually capable of controlling or limiting temperature. According to the temperature control characteristics, the contact welding repair system can be divided into three categories.

(1) constant temperature system. Provides continuous and constant heat output. For welding and repair application of the SMT components, should run in 335 ~ 365 ℃ temperature range.

(2) limited temperature system. Keep the temperature in an optimal range and do not transfer heat continuously, this feature can prevent overheating, but the heating speed of the system is slow. Limit temperature contact welding system applied in SMT components for the operating temperature range in 285 ~ 315 ℃.

(3) controllable temperature system. Can provide a more efficient heat output capacity, the system usually are controlled within 10 ℃ temperature deviation, can't transfer heat in a row, but since nearly should response time and temperature to the temperature control system than the limit temperature. This kind of contact welding system for operating temperature fan control in 285 ~ 315 ℃.

Contact welding has the following characteristics: welding cost is relatively low, easy to buy for use; The pre-fixed components can be easily removed by welding rings. The electric soldering ring must contact the welding point and the pin directly to obtain the corresponding heating efficiency; Electrocautery head or welding ring without welding temperature limit or control are vulnerable to temperature shock, which may damage ceramic components, especially multi-layer capacitors.

That's all for today's sharing,and we are also the Custom PCB Manufacturer,if you have any demand,just feel free to contact us.