Company News

Aug. 22, 2024

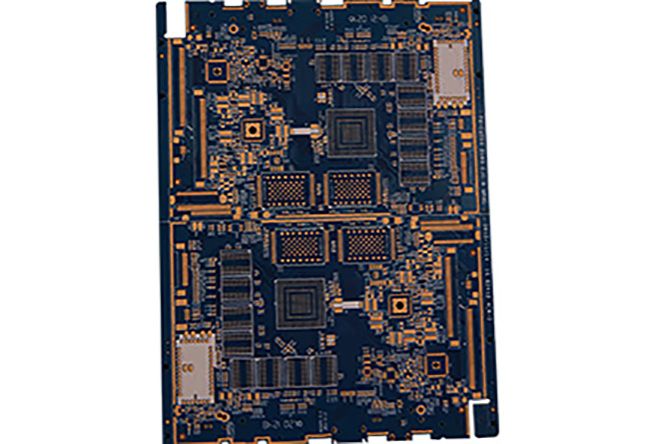

In PCB printed circuit board components, including the Double Side Rigid PCB,there are three main ways of binding or adhesion between pollutants and components, which are molecular and molecular binding, also known as physical bond binding; The bonding of atoms to one another, also known as chemical bonding; Contaminants are embedded in granular form in materials such as welding masks or electroplating deposits, known as inclusions.

The core of the cleaning mechanism is to break the chemical bond or physical bond between pollutants and PCB, so as to achieve the purpose of separating pollutants from components. Since this process is an endothermic reaction, it must be supplied to achieve the above purpose.

Using appropriate solvents, through the dissolving reaction and saponification reaction between pollutants and solvents to provide energy, can destroy the binding force between them, so that the pollutants dissolved in the solvent, thus achieving the purpose of pollutants removal.

In addition, specific water can be used to remove contaminants left ,including 4 layers LED Printed Circuit Board by the water-soluble flux on the assembly.

Due to the PCB printed circuit board components in the welding after the degree of contamination, different types of pollutants and different products on the component cleaning after the cleanliness requirements are different, therefore, there are many types of cleaning agent. So, how to choose the right cleaning agent? The following SMT processing plant technicians to introduce some of the basic requirements for cleaning agent.